Design Testing & Verification

If you already have an existing development that may be experiencing intermittent problems, we are able to put your design through rigorous testing to identify any weakness or deviation from the design specification.

Utilising the design information, and any specifications that may exist, we are able to devise a suitable testing plan to put both technology and functionality through its paces to uncover any issues before products are with your customers. This may include for example:

- Test Lab “soak test” of a design repetitively testing functionality of both hardware and software in a variety of situations, including continual environmental testing such as thermal cycling, shock/vibration, EMC.

- Automated Test Equipment (ATE) rigs for repeatable design test, configuration and firmware programming, both electronic, software and electro-mechanical for user interfaces with buttons etc.

- Reliability software simulations that can predict over-stress and failure modes.

- Design additions such as built in self testing (BIST) features to identify and self correct operational problems.

- Software static analysis & code module/unit testing to identify any weaknesses in software code.

We are able to re-use test rig designs to create production test equipment that can be shipped to your production factory to ensure consistency of quality of product manufactured.

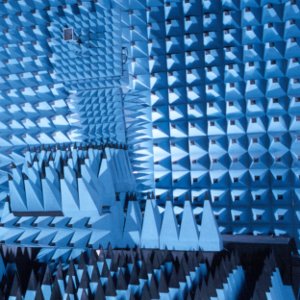

Electromagnetic Compatibility (EMC) Troubleshooting & Lab Test / Certification Support

We have particular expertise in electromagnetic compatibility (EMC) and Signal Integrity (SI) analysis at both a design and final testing stage. Our experience not only helps us understand in detail how a design can more easily meet regulatory compliance, but also how by improving EMC and SI characteristics of a design can reduce manufacturing costs, improve performance/reliability and increase product lifetime. Our expertise in this includes:

- Manage compliance activities (e.g. CE/FCC) testing for a variety of product types, including generic product (EN61000), radio (R&TTE), IT equipment (ITE), medical (EN60601), instrumentation, ATEX, UL and many others.

- Technical File documentation.

- Design stage activities such as Design for EMC & SI

- On and off-site pre-compliance activities during design and final testing stage for lower cost exploratory/remedial testing prior to expensive final compliance lab tests.

We are able to completely handle these activities on your behalf or in partnership with your technical team, including witnessing 3rd party lab testing, type approvals and any remedial action that may need to be taken on the spot during final lab testing.